In the fast-paced world of logistics, efficiency isn’t just a goal—it’s an absolute necessity! As customer demands soar, warehouses are under immense pressure to maximize storage capabilities, accelerate order fulfilment, and eliminate costly errors.

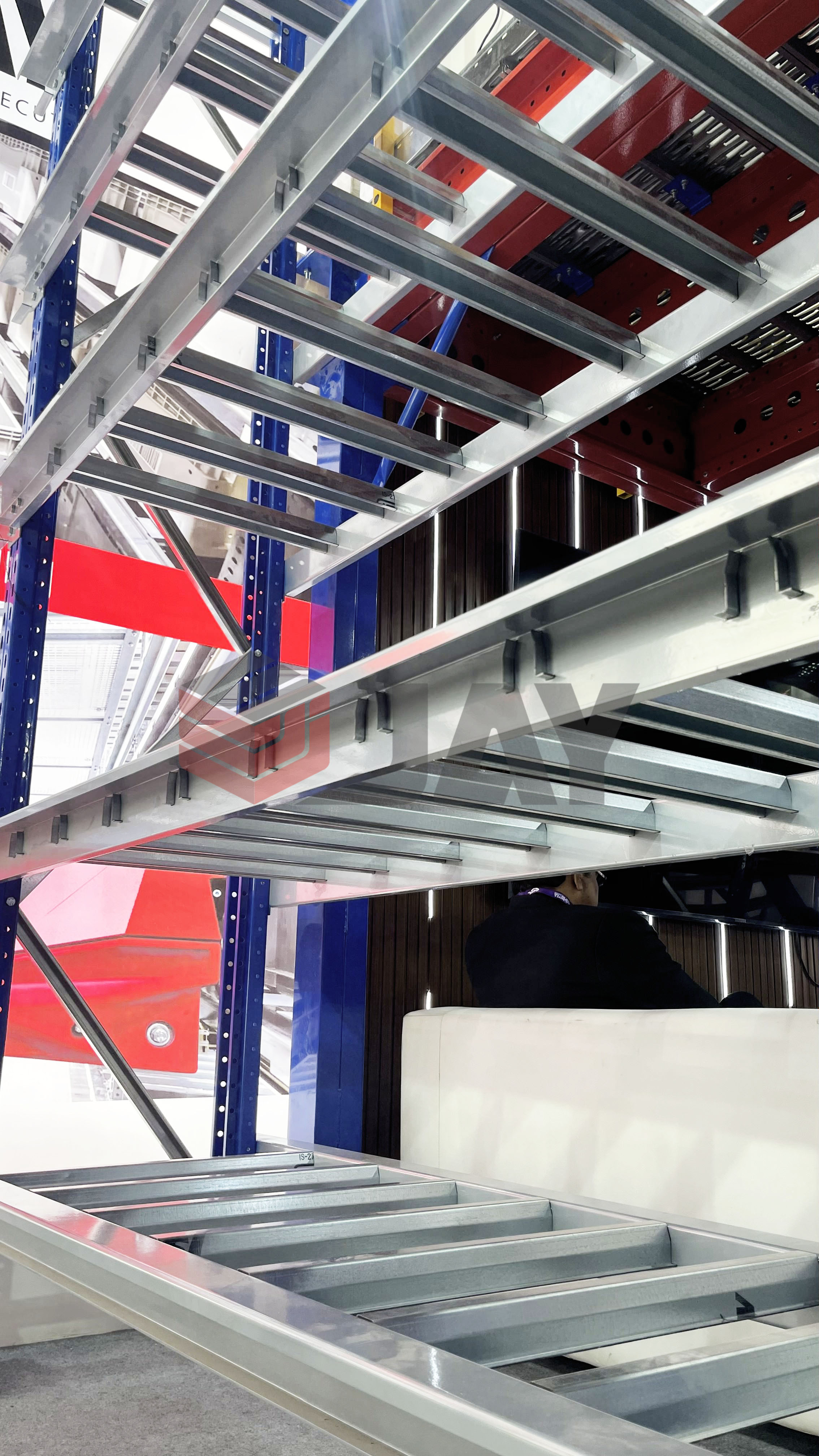

Introducing the Multi Shuttle Racking System.

If you’re looking for a solution that can transform your operations with state-of-the-art automation, keep reading!

What is a Multi Shuttle Racking System?

The Multi Shuttle Racking System is an advanced Automated Storage and Retrieval System (AS/RS) tailored for high-density storage operations. Unlike traditional static racking systems that can be bulky and slow, this innovative technology harnesses the power of a robotic shuttle, to effortlessly transport goods within a racking structure.

Rapid and seamless order fulfilment—perfect for industries like e-commerce, pharmaceuticals, automotive, and FMCG.

How Does It Work?

- Racking: High-density storage racks for totes, cartons, or bins, pallets.

- Robotic Shuttle: Autonomous shuttle carriers that move horizontally within the racking levels to retrieve and place goods.

- Lifts and Conveyors: Vertical lifts transport items between racking levels while conveyors move items to pick stations.

- Warehouse Management System (WMS):The brain of the operation, optimizing shuttle movements, tracking inventory, and ensuring seamless fulfilment.

How Does the Process Work

- Order Placed? The WMS assigns a robotic shuttle.

- Swift Retrieval! The Shuttle fetches the required item.

- Smooth Transit! The lift delivers the fetched item.

- Ready to Go! The order is processed and dispatched.

Fast, Seamless, And 100% Accurate!

Why Your Warehouse Needs A Multi-Shuttle Racking System

Still on the fence? Here are some compelling reasons to consider integrating a Multi Shuttle Racking System into your warehouse operations:

- Maximize Storage Space: Shuttles operate continuously with minimal downtime. It drastically reduces picking and retrieval times compared to manual processes.

- Error-Free Picking: Automation significantly minimizes human intervention, reducing the risk of errors. It is crucial in industries like pharmaceuticals and e-commerce, where accurate order fulfilment can make or break your reputation.

- Cut Operational Costs: With decreased labour requirements and optimized space utilization, warehouses can achieve lower operational costs and higher productivity.

- Scalable & Future-Proof: The modular design allows for easy expansion or reconfiguration based on your evolving business needs, ensuring you remain equipped to handle growth and changes in demand.

Warehouses that adopt automation through the Multi Shuttle Racking System experience a remarkable leap in operational efficiency. If you’re grappling with increasing order volumes, limited space, or sluggish fulfilment times, this innovative system is your ultimate solution!

We provide cutting-edge warehouse automation solutions tailored to your business needs.

Contact us today, and let us transform your warehouse into a high-efficiency powerhouse!

Don’t be left behind in an ever-evolving industry—invest in the future of your warehouse.